One component polyurethane waterproof coating

詳情信息

Product introduction

This product is divided into SBS modified asphalt waterproof coating, rubber modified asphalt waterproof coating, road and bridge asphalt waterproof coating. It uses thermoplastic rubber (SBS, SIS) or styrene butadiene rubber (SBR), chloroprene rubber (CR), natural rubber (NR), polyethylene (PE), polyethylene (PP), ethylene vinyl acetate copolymer (EVA), polyvinyl chloride (PVC), APAO as modifiers, and liquid road asphalt and filler And petroleum resin.

Product features

Due to the effect of temperature and machinery, the high polymer makes asphalt enter into its three-dimensional network structure and becomes an organic polymer elastomer, which greatly improves the performance of asphalt and endows the product with the characteristics of rubber.

It is convenient for construction and has a wide range of application. It has obvious advantages for the construction of complex parts.

The maintenance is convenient, and the original waterproof effect can be achieved only by partial maintenance of the damaged parts.

After curing, a seamless and complete elastic waterproof layer is formed, which improves the waterproof and impermeability of construction engineering, which can not be achieved by coiled material products.

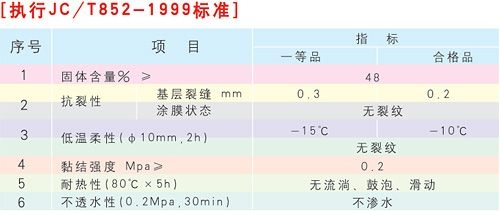

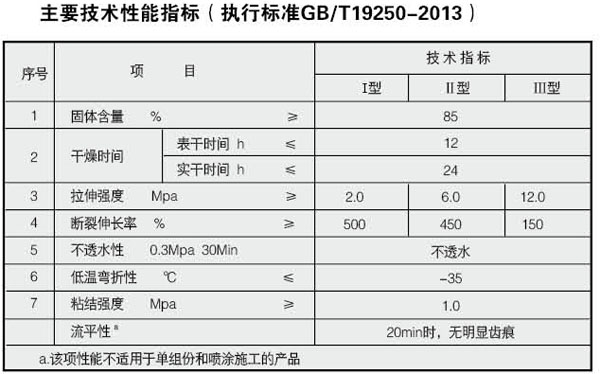

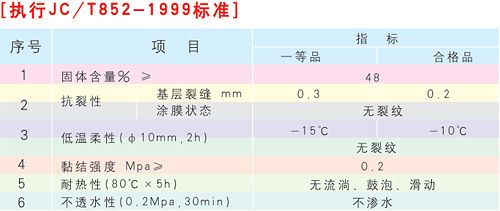

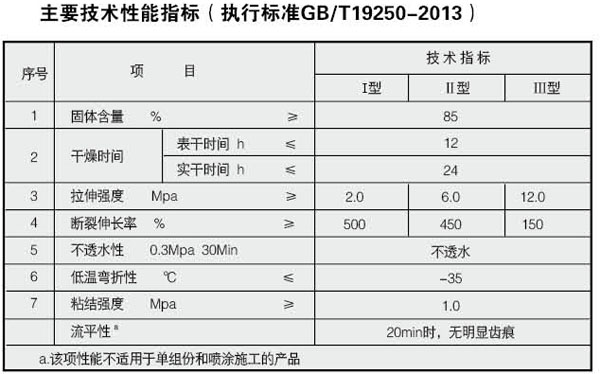

Performance criteria

Construction precautions

The base course shall be smooth, firm and free from sand, and the depression shall be leveled with mortar.

Before use, it must be stirred evenly (precipitation in the barrel is a normal phenomenon, and it can be used after mixing).

The thickness of brushing must be controlled within 0.5mm, otherwise the solvent under the surface will volatilize slowly after the surface starts to film, and there will be hand sticking phenomenon. In this case, a layer of powder can be spread on the surface, and the next construction can be carried out after wiping.

免費(fèi)獲取報(bào)價(jià)

免費(fèi)獲取報(bào)價(jià) +86-15064467521

+86-15064467521

Polymer modified asphalt waterproof coating

Polymer modified asphalt waterproof coating Silicone waterproof coating

Silicone waterproof coating Polymer cement (JS) composite waterproof coating

Polymer cement (JS) composite waterproof coating

首頁(yè)

首頁(yè)

產(chǎn)品

產(chǎn)品

電話

電話